Streamlining Workflows with Process Mapping: Identifying Bottlenecks and Driving Improvement

Every organization operates through a series of invisible workflows, and when tasks get stuck, delayed, or duplicated, the problem isn’t always effort, it’s clarity.

What is meant by process mapping and why is it essential for efficiency?

The process mapping involves the development of a flow diagram, or graphic, of a given workflow in its entirety. It provides standardized symbols (such as ovals-start / end, rectangles-activity and diamond-decision) that just help in demonstrating the flow of steps, those who must perform the tasks and possible ways.

Making visual maps of existing processes will immediately give businesses transparency, which is the initial step to achieving the key process improvement and operational excellence. This visualization is necessary since it transcends non-specific descriptions to give a common objective truth of how a process is functioning.

The primary goal is to foster a better organizational understanding of complexity, enabling teams to instantly identify inefficiencies, redundancies, and key points of failure, thereby facilitating immediate process improvement.

Why do complex workflows inevitably lead to organizational bottlenecks and hidden waste?

Complex workflow processes naturally create bottlenecks and waste in case there is no clarity regarding accountability and sequence. In the case of a process that has numerous handoffs between teams or departments, the waiting time and energy to seek approval or transfer of information can be the biggest contributor to inefficiency.

The blockages do not allow the free flow of work, which drastically raises the cycle times and annoys both employees and customers.

This is directly taken care of through process mapping wherein all handoffs are made visible, delays are quantified and any non-value-added steps that are not visible are revealed, which are all essential steps to remove organizational bottlenecks and ensure true process improvement.

What are the practical steps required to successfully create, validate, and optimize a process mapping diagram?

To successfully execute process mapping, you must follow a disciplined methodology. The first step is to select a process that is focused, has a beginning and end and engage subject matter experts (SMEs). Second, record the existing situation (what is really taking place and not what it ought to take place), recording all the activities, inputs, and decisions.

Third, to make the flowchart more comprehensible, draw it in common symbols such as the swim lane diagram or simple flowcharts. Fourth, map with the stakeholders to make sure it is correct.

Lastly, find the bottlenecks and redundant steps using the finished map and plan the future state map. To implement this better process, it would involve observation, feedback, and dedication in the process of continuous process improvement- the final aim of the whole process mapping exercise.

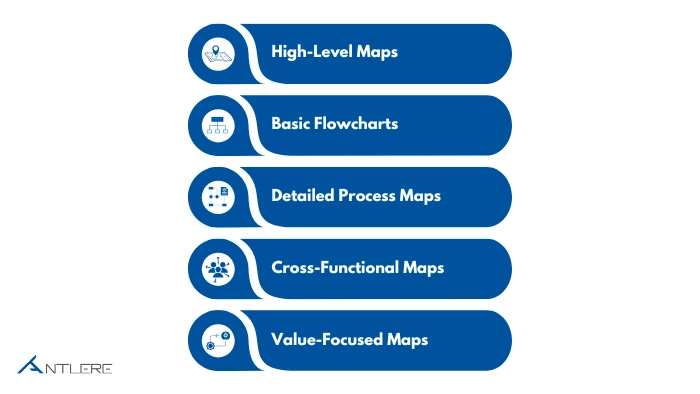

What types of process maps should be used to analyze different levels of organizational detail?

There are several types of process maps, each designed to capture a different level of detail or focus:

- High-Level Maps: These are top-down views showing key phases (Supplier, Input, Process, Output, Customer – SIPOC) but omitting fine detail.

- Basic Flowcharts: Simple, sequential diagrams showing the flow of a single process.

- Detailed Process Maps: These show every action, decision point, and contingency for a specific subprocess.

- Cross-Functional Maps: Also known as a swim lane diagram, this map separates the workflow by role, person, or department. It is critical in bringing out the inter-departmental handoffs and outlining the responsibility of various individuals on what is essential in solving the bottlenecks of various teams.

- Value-Focused Maps: One of the Lean Six Sigma tools is a value stream map (VSM), where the entire process of a product or service is documented, and the data it includes cycle time, and the points where wasting is occurring.

Together, these map types allow you to analyze the process from a macro-level strategic overview down to the minutiae of the smallest task, giving you the tools to spot opportunities for process improvement.

Conclusion

Process mapping is not a paperwork, but a proactive approach towards transformation of operations. With all the steps, decision points, and handoff points being visible because of tools, such as the swim lane diagram and the value stream map, the organization will be able to conquer the hidden waste.

Such a systematic procedure is the surest means of locating and eradicating the bottlenecks to make sure that the resources are not wasted in vain and that each member of the team is aware of his or her part in the larger process.

By adopting process mapping, it is necessary to dedicate themselves to constant process enhancement, whereby the clarity of workflow can be turned into quantifiable results that bring in efficiency and standardization, as well as customer satisfaction. It is time to start mapping your processes and transform it into a smoother, more profitable future.